The overall control of this equipment utilizes Siemens PLC, and the weighing sensor adopts the brand of Toriduo, ensuring more precise accuracy control during the filling process. The production line consists of an automatic barrel feeder, weighing a...

The overall control of this equipment utilizes Siemens PLC, and the weighing sensor adopts the brand of Toriduo, ensuring more precise accuracy control during the filling process.

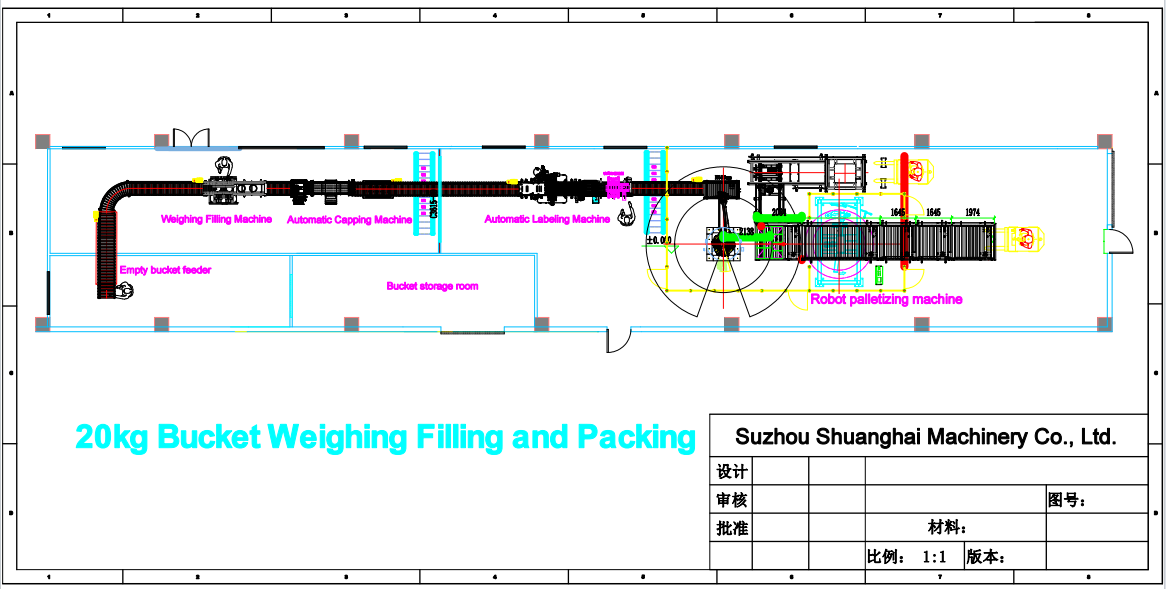

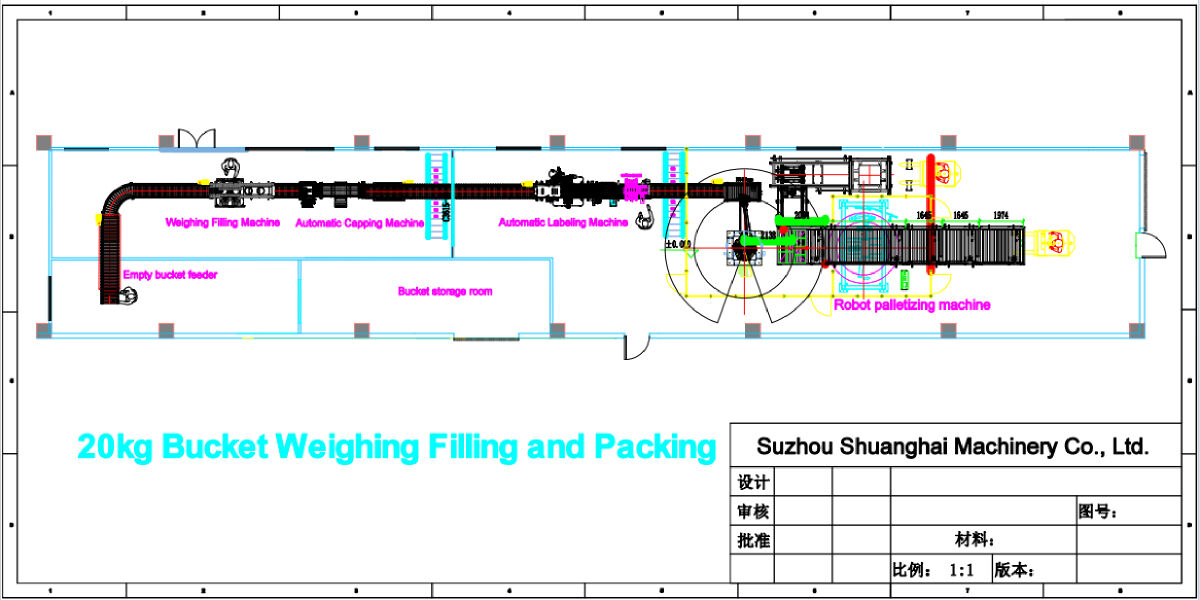

The production line consists of an automatic barrel feeder, weighing and filling machine, capper, labeler, and automatic palletizer. The entire line is automatically controlled and can be operated by only two people, saving labor costs.

Performance characteristics of fully automatic barrel filling production line:

1. Automatic barrel feeding, with the option to nest plastic bags inside the barrel.

2. The filling nozzle is designed to be movable up and down, allowing it to submerge into the bottom of the barrel for filling, thus eliminating splashes. The nozzle is of an internal resistance type, which prevents drips and leaks.

3. The filling trigger has a dual determination process to prevent material leakage caused by missing barrels.

4. The capping station is designed with multiple sets of cap storage bins, allowing for cap replacement without stopping the capping machine.

5. The labeling station can choose between single-label or dual-label mode to achieve simultaneous labeling of the barrel body and top cover.

6. The back-end is equipped with a robotic palletizer and a PE stretch wrap packaging machine, which can complete the automatic stacking and packaging of products, improve logistics efficiency, reduce manual intervention, and ensure neat and aesthetically pleasing packaging.