Understanding Modern Manufacturing Efficiency Through Automated Solutions

In today's fast-paced manufacturing environment, efficiency isn't just a buzzword – it's the key to survival and growth. At the heart of many successful production lines lies the filling machine, a sophisticated piece of equipment that has revolutionized how manufacturers handle liquid, semi-liquid, and powder products. This automated solution has become indispensable across industries, from food and beverage to pharmaceuticals and cosmetics, offering precision, speed, and reliability that manual processes simply cannot match.

The impact of a filling machine extends far beyond simple container filling. These systems represent a crucial investment that can transform manufacturing operations, boost productivity, and deliver consistent quality that meets stringent industry standards. As we explore the multifaceted benefits of these machines, we'll uncover how they're reshaping the manufacturing landscape and driving operational excellence.

Core Benefits of Implementing Filling Machine Technology

Enhanced Production Speed and Output

When manufacturers integrate a filling machine into their production line, one of the most immediate and noticeable improvements is the dramatic increase in production speed. Modern filling machines can process hundreds, or even thousands, of units per hour with remarkable precision. This heightened throughput capability allows manufacturers to meet growing demand without sacrificing quality or accuracy.

The automated nature of these systems means they can operate continuously with minimal downtime, maintaining consistent output levels throughout entire production shifts. Unlike manual filling processes, which are subject to human fatigue and variance, a filling machine maintains its pace and precision hour after hour, leading to significantly higher daily production volumes.

Reduced Labor Costs and Human Error

The implementation of a filling machine substantially reduces the need for manual labor in the filling process. While skilled operators are still essential for oversight and quality control, the automation of the filling process means fewer workers are needed for basic filling tasks. This not only leads to direct labor cost savings but also minimizes the risk of repetitive strain injuries associated with manual filling operations.

Human error, which can result in inconsistent fill levels, spills, and product waste, is virtually eliminated with automated filling systems. The precision control mechanisms in modern filling machines ensure each container receives exactly the right amount of product, reducing waste and improving overall efficiency.

Technical Advantages of Modern Filling Systems

Precision Control and Accuracy

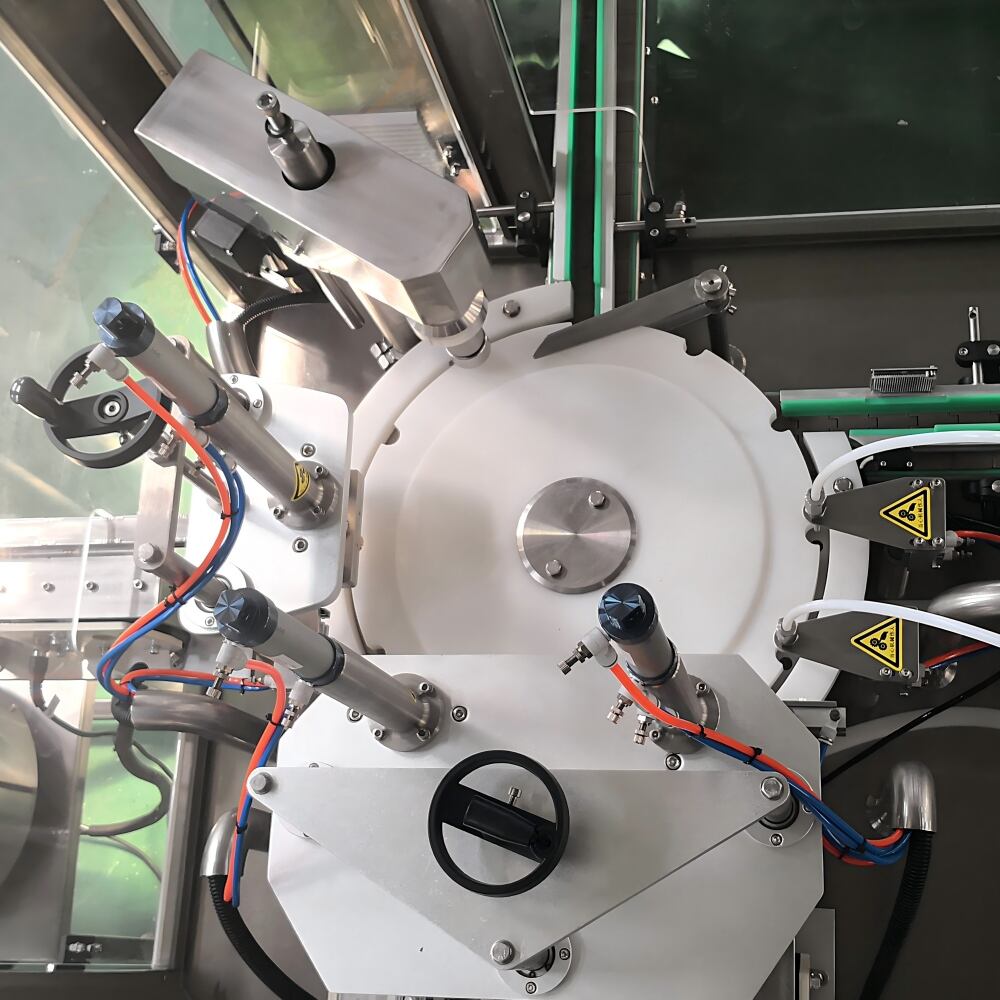

Modern filling machines incorporate advanced sensors and control systems that ensure unprecedented accuracy in dispensing products. These sophisticated systems can maintain fill tolerances within fractions of a milliliter, ensuring consistent product quality and compliance with regulatory requirements. The precision control extends to various aspects of the filling process, from flow rate adjustment to container positioning.

The ability to fine-tune filling parameters allows manufacturers to handle different product viscosities and container sizes with minimal changeover time. This versatility makes filling machines invaluable for manufacturers who produce multiple product lines or need to adjust their production specifications frequently.

Integration with Industry 4.0 Technologies

Contemporary filling machines are increasingly equipped with smart features that align with Industry 4.0 principles. These machines can collect and analyze data in real-time, providing valuable insights into production efficiency, maintenance needs, and quality control metrics. The integration capabilities allow manufacturers to connect their filling operations with broader manufacturing execution systems (MES) and enterprise resource planning (ERP) platforms.

The data-driven approach enables predictive maintenance scheduling, reducing unexpected downtime and optimizing machine performance. Additionally, remote monitoring capabilities allow technical teams to identify and resolve issues quickly, maintaining high operational efficiency.

Operational Impact on Manufacturing Processes

Streamlined Production Workflows

The introduction of a filling machine fundamentally transforms production workflows. These systems can be seamlessly integrated with existing conveyor systems, capping machines, and labeling equipment to create a continuous, automated production line. The synchronized operation of these components eliminates bottlenecks and reduces the need for intermediate product handling.

The streamlined workflow extends beyond the filling station itself. Automated filling systems can be programmed to coordinate with upstream and downstream processes, ensuring smooth material flow and optimal resource utilization throughout the entire production cycle.

Quality Assurance and Compliance

Quality control is paramount in manufacturing, and filling machines contribute significantly to maintaining consistent product quality. Built-in inspection systems can monitor fill levels, detect damaged containers, and ensure proper sealing, all while maintaining production speed. These quality checks happen in real-time, allowing for immediate corrective action when necessary.

Modern filling machines also help manufacturers meet increasingly stringent regulatory requirements. The ability to maintain detailed production records, including fill weights, speeds, and quality metrics, supports compliance documentation and traceability initiatives.

Return on Investment Considerations

Long-term Cost Benefits

While the initial investment in a filling machine may be substantial, the long-term financial benefits often justify the expense. Reduced labor costs, minimal product waste, and increased production capacity contribute to a positive return on investment. The durability and reliability of modern filling machines, combined with proper maintenance, ensure years of efficient operation.

Manufacturers also benefit from reduced inventory carrying costs, as automated filling systems allow for more precise production planning and just-in-time manufacturing capabilities. The consistency in output helps optimize supply chain management and reduce warehousing needs.

Market Competitiveness and Growth Potential

Investing in a filling machine positions manufacturers to compete more effectively in their markets. The ability to handle larger production volumes while maintaining quality enables businesses to take on bigger contracts and expand their market presence. The flexibility to quickly adjust production parameters also allows manufacturers to respond rapidly to changing market demands.

The enhanced production capabilities provided by filling machines enable manufacturers to explore new product lines and packaging options, creating opportunities for business growth and diversification. This technological advantage can be particularly valuable in markets where speed to market and production agility are crucial competitive factors.

Frequently Asked Questions

What types of products can be handled by filling machines?

Filling machines can handle a wide range of products, including liquids, semi-liquids, powders, and granules. Modern machines can be configured for various viscosities and product characteristics, making them suitable for industries from food and beverage to chemicals and pharmaceuticals.

How long does it take to see a return on investment from a filling machine?

The ROI period typically ranges from 12 to 36 months, depending on factors such as production volume, labor costs, and current operational efficiency. Many manufacturers report significant cost savings within the first year of implementation.

What maintenance requirements should manufacturers expect?

While filling machines are generally robust and reliable, they require regular maintenance including cleaning, calibration, and component inspection. Modern machines often feature predictive maintenance systems that help schedule service intervals and minimize unexpected downtime.

Can existing production lines be upgraded with new filling machine technology?

Yes, most modern filling machines are designed to integrate with existing production infrastructure. Manufacturers can often upgrade their lines incrementally, starting with the filling station and expanding automation capabilities over time as needed.