Revolutionizing Food Production Through Automated Sauce Processing

The food industry continues to evolve at an unprecedented pace, with sauce manufacturing playing a pivotal role in meeting consumer demands. At the heart of this evolution lies the sauce filling machine, an essential piece of equipment that transforms how food manufacturers handle liquid and semi-liquid product packaging. These sophisticated systems combine precision, speed, and reliability to keep pace with the ever-growing market demands while maintaining the highest quality standards.

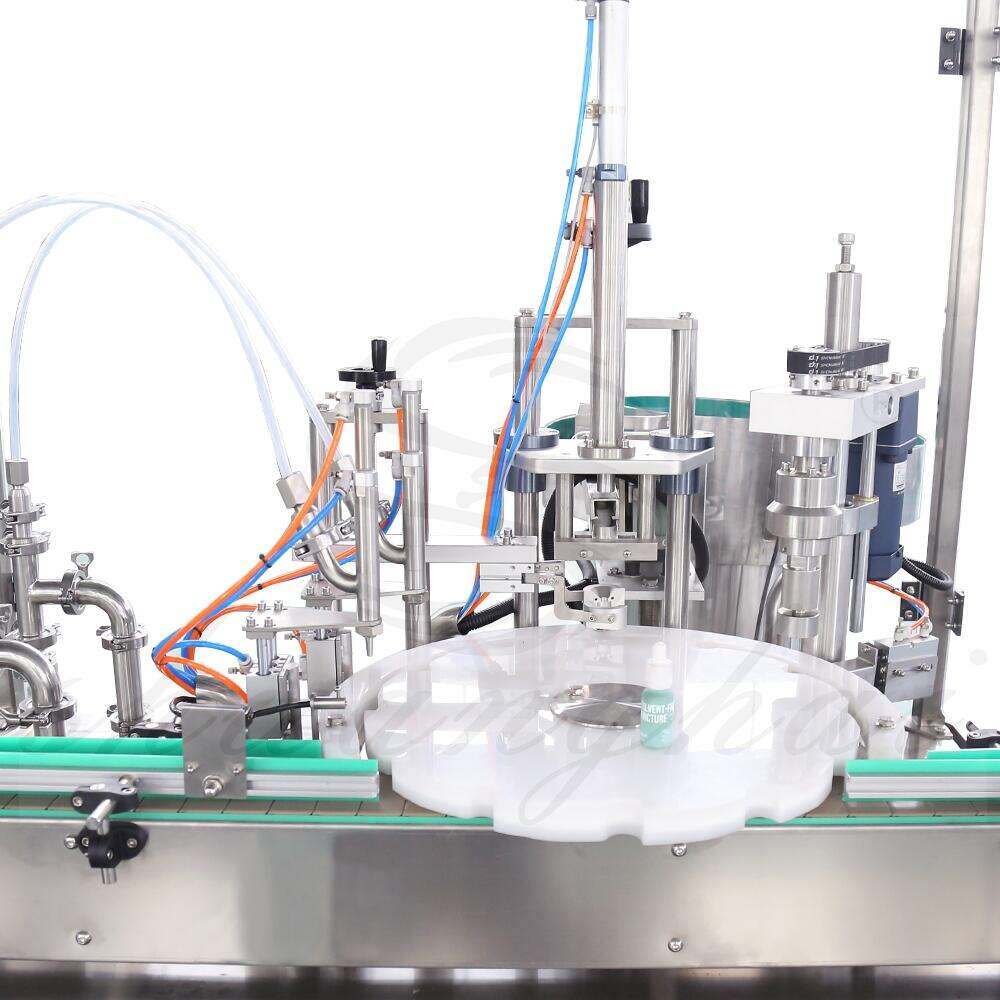

Modern sauce filling machines represent a significant leap forward in food processing technology, offering capabilities that manual filling operations simply cannot match. From traditional condiments to exotic sauces, these machines handle diverse product viscosities while ensuring consistent fill levels, maintaining product integrity, and maximizing production efficiency.

Advanced Features of Modern Sauce Filling Systems

Precision Control and Accuracy

Today's sauce filling machine technology incorporates advanced control systems that ensure precise filling volumes with minimal deviation. Digital controls allow operators to adjust fill parameters with microscopic precision, typically achieving accuracy rates of ±0.5% or better. This level of precision not only ensures regulatory compliance but also minimizes product waste and optimizes cost efficiency.

The integration of servo-driven pumps and sophisticated flow meters enables these machines to maintain consistent fill levels regardless of changes in product viscosity or temperature. This technological advancement is particularly crucial when handling premium sauces where exact portioning directly impacts product quality and production costs.

Versatility in Product Handling

Modern sauce filling machines are designed to handle a wide spectrum of products, from water-thin sauces to thick pastes. Customizable nozzle designs and adjustable filling mechanisms allow manufacturers to switch between different products without requiring extensive system modifications. This versatility is essential for food manufacturers who produce multiple sauce varieties on the same production line.

The ability to handle various container sizes and types further enhances the machine's versatility. Whether filling glass bottles, plastic containers, or flexible pouches, a single sauce filling machine can accommodate multiple packaging formats with minimal changeover time.

Efficiency and Production Output Enhancement

Speed and Volume Capabilities

Industrial sauce filling machines can achieve impressive production rates, often processing hundreds of containers per minute. This high-speed capability is crucial for meeting large-scale production demands and maintaining competitive advantage in the market. Advanced models incorporate parallel filling stations that can simultaneously fill multiple containers, further increasing throughput.

The integration of automated feeding systems and conveyor mechanisms ensures continuous operation with minimal manual intervention. This seamless workflow significantly reduces production bottlenecks and maintains consistent output levels throughout extended production runs.

Reduced Downtime and Maintenance Requirements

Modern sauce filling machines are built with durability in mind, featuring robust construction and wear-resistant components that minimize maintenance requirements. Quick-change parts and tool-less adjustments enable rapid product changeovers, reducing downtime between production runs. The implementation of preventive maintenance programs, supported by smart monitoring systems, helps identify potential issues before they impact production.

Self-cleaning features and CIP (Clean-in-Place) systems significantly reduce the time required for sanitation procedures. This automation of cleaning processes not only ensures consistent sanitary conditions but also maximizes available production time.

Quality Assurance and Safety Features

Contamination Prevention Systems

Advanced sauce filling machines incorporate multiple safeguards to prevent product contamination. HEPA-filtered air systems maintain positive pressure in filling areas, while automated cap handling systems minimize human contact with product contact surfaces. These features are especially crucial in aseptic filling operations where maintaining product sterility is paramount.

The integration of vision systems and sensors provides real-time monitoring of fill levels, cap placement, and label alignment. Any deviations from preset parameters trigger immediate alerts, allowing operators to address issues before they result in significant product waste.

Compliance with Industry Standards

Modern sauce filling machines are designed to meet stringent industry regulations and safety standards. From FDA compliance to HACCP requirements, these machines incorporate features that facilitate regulatory compliance while maintaining efficient production flows. Documentation systems automatically record operational parameters, simplifying audit processes and ensuring traceability.

The implementation of allergen control protocols and quick-changeover procedures helps manufacturers maintain strict separation between different products, preventing cross-contamination and ensuring product safety.

Future Trends and Innovations

Smart Manufacturing Integration

The next generation of sauce filling machines is embracing Industry 4.0 principles, incorporating IoT sensors and advanced analytics capabilities. These smart features enable real-time monitoring of machine performance, predictive maintenance scheduling, and automated quality control systems. The resulting data insights help manufacturers optimize production parameters and reduce operational costs.

Cloud connectivity allows remote monitoring and adjustment of filling operations, enabling manufacturers to respond quickly to production issues and maintain optimal performance levels. This connectivity also facilitates integration with enterprise resource planning systems for improved production planning and inventory management.

Sustainability Enhancements

Environmental considerations are driving innovations in sauce filling machine design. New models incorporate energy-efficient components and water-saving features that reduce resource consumption while maintaining high production rates. Advanced recycling systems recover and reuse cleaning solutions, minimizing environmental impact and operating costs.

The development of filling systems compatible with eco-friendly packaging materials supports manufacturers' sustainability initiatives while meeting consumer demands for environmentally responsible products.

Frequently Asked Questions

What is the typical return on investment for a sauce filling machine?

The return on investment for a sauce filling machine typically ranges from 12 to 24 months, depending on production volume and operational efficiency gains. Factors such as reduced labor costs, increased production capacity, and minimized product waste contribute to rapid cost recovery.

How do sauce filling machines handle products of different viscosities?

Modern sauce filling machines use adjustable pump systems and specialized nozzle designs that can be calibrated for different product consistencies. Temperature control systems and variable speed drives ensure accurate filling across a wide range of viscosities, from thin vinaigrettes to thick pasta sauces.

What maintenance requirements should be considered for sauce filling machines?

Regular maintenance typically includes daily cleaning procedures, weekly inspection of wear components, and quarterly comprehensive service checks. Most manufacturers recommend preventive maintenance schedules that include seal replacement, calibration verification, and thorough system inspection to ensure optimal performance and longevity.