Transforming Production Efficiency Through Automated Filling Solutions

Modern manufacturing facilities are constantly seeking ways to streamline their operations and maximize productivity. At the heart of many successful production lines lies the filling machine, an innovative piece of equipment that has revolutionized how products are packaged and prepared for distribution. These sophisticated systems have become indispensable across various industries, from food and beverage to pharmaceuticals and cosmetics, offering unprecedented levels of precision, speed, and reliability.

The integration of filling machines into production processes represents a significant leap forward in manufacturing technology. These systems not only enhance operational efficiency but also ensure consistent product quality while reducing waste and human error. As we delve deeper into the advantages of filling machines, we'll explore how they're reshaping the future of industrial production and delivering value across multiple business dimensions.

Enhanced Production Speed and Efficiency

Accelerated Output Rates

When comparing manual filling operations to automated filling machine systems, the difference in production speed is remarkable. A modern filling machine can process hundreds or even thousands of units per hour, depending on the model and application. This dramatic increase in output capacity allows manufacturers to meet growing demand without expanding their facility footprint or significantly increasing operational costs.

The consistent operation of filling machines maintains a steady production rhythm, eliminating the natural variations and fatigue-related slowdowns associated with manual filling. This sustained performance level ensures predictable production schedules and improved planning capabilities for manufacturing facilities.

Reduced Labor Requirements

Implementing a filling machine significantly reduces the number of personnel needed for production operations. While traditional manual filling processes might require multiple operators working in shifts, a single filling machine can often be monitored by one trained operator. This reduction in labor requirements not only decreases operational costs but also allows companies to reallocate their workforce to more strategic tasks that require human expertise and decision-making.

Moreover, the automated nature of filling machines minimizes the physical strain on workers, reducing the risk of repetitive stress injuries and associated workplace health issues. This leads to improved employee satisfaction and reduced absenteeism, contributing to overall operational stability.

Superior Accuracy and Consistency

Precise Volume Control

One of the most significant advantages of using a filling machine is its ability to maintain extremely precise filling volumes. Advanced filling machines utilize sophisticated measurement systems and controls to ensure each container receives exactly the specified amount of product. This precision is particularly crucial in industries where slight variations can impact product quality or regulatory compliance.

Modern filling machines can achieve accuracy rates of 99.9% or higher, virtually eliminating over-filling or under-filling issues. This level of precision not only ensures customer satisfaction but also helps manufacturers optimize their material usage and reduce waste.

Quality Assurance Features

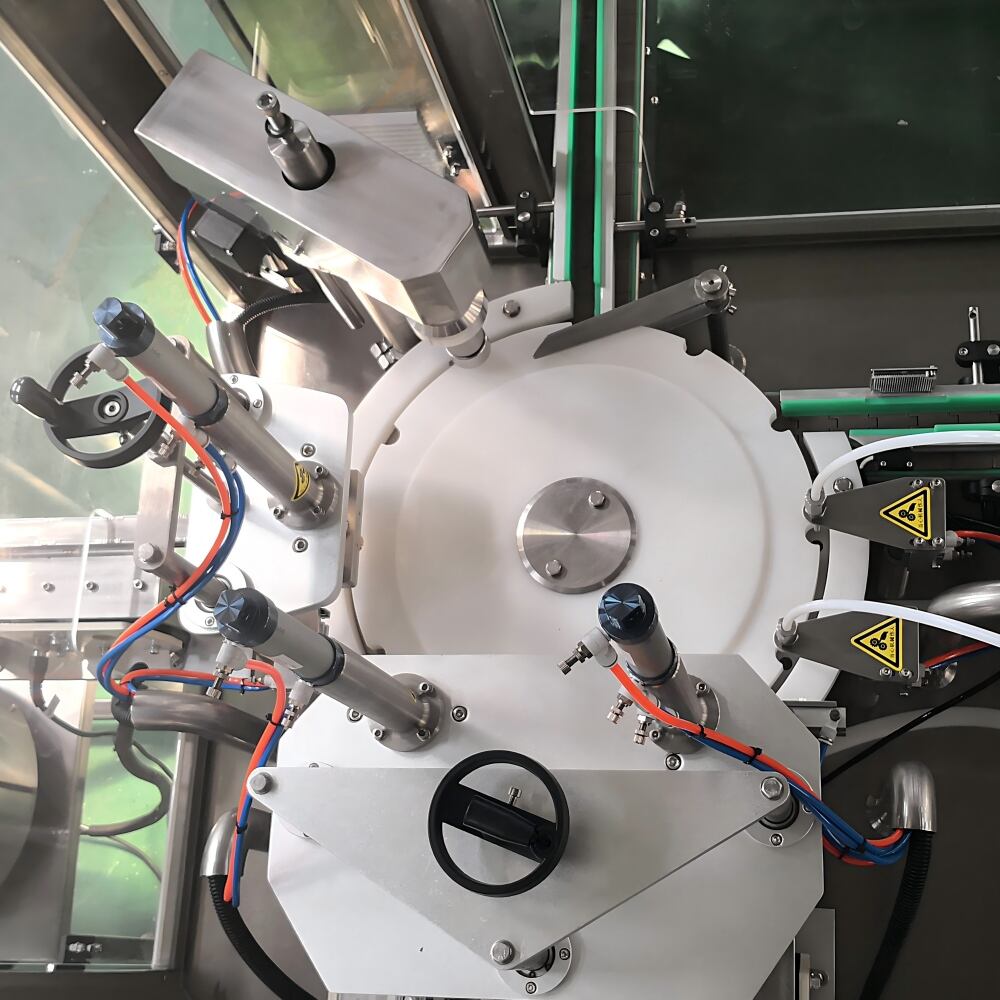

Today's filling machines come equipped with advanced quality control features that monitor every aspect of the filling process. Built-in sensors can detect irregularities in fill levels, container positioning, and product characteristics, automatically rejecting any units that don't meet predetermined specifications. This automated quality control system operates continuously, maintaining consistent product quality throughout extended production runs.

The integration of quality assurance features within the filling machine also provides valuable data for process improvement and regulatory compliance. Detailed production records can be automatically generated, supporting traceability requirements and facilitating quick response to any quality-related issues.

Cost-Effective Operations

Reduced Product Waste

The precision control offered by filling machines significantly reduces product waste compared to manual filling operations. By eliminating overfilling and minimizing spillage, manufacturers can save substantial amounts of product over time. This reduction in waste is particularly valuable when working with expensive materials or products with strict handling requirements.

Additionally, modern filling machines often incorporate product recovery systems that can reclaim and reuse product that would otherwise be lost during system cleaning or changeovers. This feature further enhances cost efficiency and supports environmental sustainability initiatives.

Lower Long-term Operating Costs

While the initial investment in a filling machine may be significant, the long-term cost benefits often provide an attractive return on investment. Reduced labor costs, improved efficiency, and minimized waste contribute to lower per-unit production costs. Furthermore, the durability and reliability of modern filling machines mean less downtime for repairs and maintenance, resulting in more consistent production schedules.

The energy efficiency of contemporary filling machines also contributes to cost savings. Many models incorporate energy-saving features and optimize power consumption during operation, helping to reduce utility costs while supporting environmental sustainability goals.

Versatility and Adaptability

Multiple Product Compatibility

Modern filling machines are designed to handle a wide range of products with different viscosities, temperatures, and chemical properties. This versatility allows manufacturers to use the same equipment for multiple product lines, maximizing the return on their investment. Quick-change components and easily adjustable settings facilitate rapid product changeovers with minimal downtime.

The ability to handle various container sizes and types further enhances the versatility of filling machines. Many systems can be quickly adapted to work with different container shapes, sizes, and materials, providing flexibility to meet changing market demands or launch new product variants.

Scalable Solutions

As businesses grow, filling machines can often be upgraded or modified to accommodate increased production demands. Modular designs allow for the addition of new features or capacity expansion without requiring a complete system replacement. This scalability helps protect the initial investment while providing a path for future growth.

The integration capabilities of modern filling machines also allow them to be easily incorporated into existing production lines or connected with other automated systems. This adaptability ensures that the filling machine can evolve along with other production technologies and continue to meet changing business needs.

Frequently Asked Questions

How long does it take to recover the investment in a filling machine?

The return on investment period for a filling machine typically ranges from 12 to 24 months, depending on factors such as production volume, labor costs, and current operational efficiency. Many manufacturers report faster payback periods due to immediate improvements in productivity and reduction in waste.

What maintenance requirements should be expected for a filling machine?

Modern filling machines require regular preventive maintenance, including cleaning, calibration, and component inspection. However, these maintenance needs are generally straightforward and can be scheduled during planned downtime. Many manufacturers offer predictive maintenance programs and remote monitoring to minimize unexpected issues.

Can filling machines handle both liquid and viscous products?

Yes, many filling machines are designed to handle products with varying viscosities. Different filling mechanisms and nozzle designs can be implemented to accommodate everything from thin liquids to thick pastes. Some machines offer interchangeable components to optimize performance for specific product types.

What safety features are included in modern filling machines?

Contemporary filling machines incorporate numerous safety features, including emergency stop systems, guard interlocks, pressure monitoring, and automatic shut-off mechanisms. These systems protect both operators and products while ensuring compliance with industrial safety regulations.