Modern manufacturing facilities demand precision, speed, and reliability when it comes to liquid filling operations. In today's competitive landscape, production lines must achieve maximum throughput while maintaining consistent quality standards. The linear type filling machine has emerged as a cornerstone technology for high-speed filling applications across multiple industries, from pharmaceuticals and cosmetics to food and beverage production. These sophisticated systems offer unparalleled efficiency and accuracy that make them indispensable for manufacturers seeking to optimize their production capabilities.

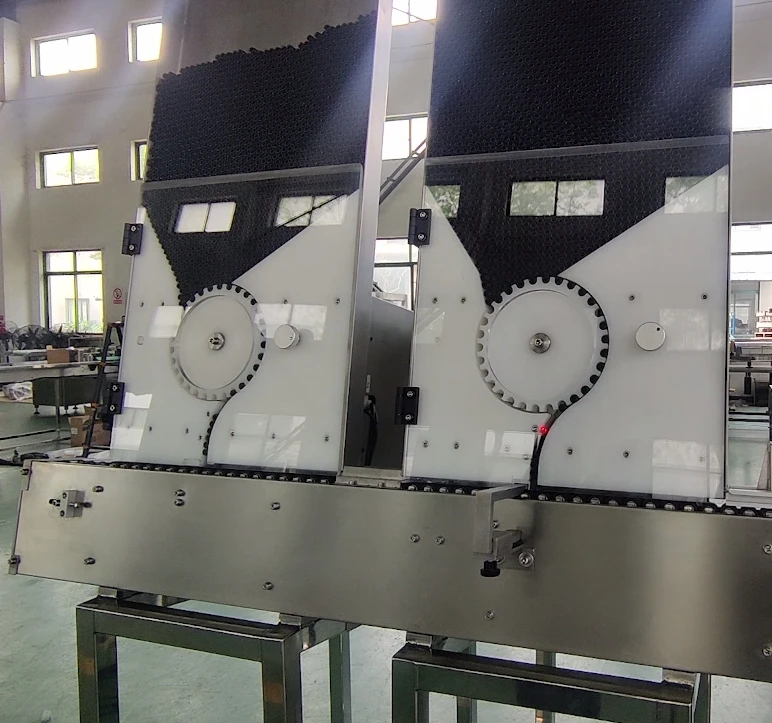

The architecture of linear filling systems fundamentally differs from rotary alternatives, providing distinct advantages for specific production requirements. Unlike circular motion systems, linear machines move containers in a straight-line configuration, allowing for easier integration with existing conveyor systems and packaging lines. This design philosophy creates opportunities for enhanced flexibility in production setup and maintenance procedures. The straight-line approach also facilitates better operator access and visibility during production runs, contributing to improved quality control and troubleshooting capabilities.

Core Design Principles and Engineering Excellence

Structural Foundation and Mechanical Precision

The mechanical foundation of a linear type filling machine relies on robust steel construction and precision-engineered components that ensure long-term reliability. The frame design incorporates vibration dampening features and thermal expansion compensation to maintain accuracy across varying operating conditions. Critical components such as filling valves, pneumatic cylinders, and servo motors are mounted on precision-machined surfaces that provide consistent positioning and minimal wear over extended operation periods. The modular construction approach allows for easy component replacement and system upgrades without requiring complete line shutdown.

Advanced bearing systems and linear guides provide smooth, consistent motion throughout the filling cycle, reducing mechanical stress and extending component lifespan. The integration of high-grade stainless steel construction ensures compatibility with aggressive cleaning chemicals and sanitizing procedures required in pharmaceutical and food applications. Precision machining tolerances maintain consistent fill volumes and minimize product waste, contributing to overall production efficiency and cost reduction.

Control System Integration and Automation

Modern linear filling machines incorporate sophisticated programmable logic controllers that provide precise timing control and system coordination. The control architecture enables real-time monitoring of critical parameters including fill volume, filling speed, container positioning, and system diagnostics. Advanced human-machine interfaces offer intuitive operation and comprehensive data logging capabilities that support quality assurance and regulatory compliance requirements. The control system architecture supports integration with enterprise resource planning systems and manufacturing execution systems for seamless production management.

Servo motor technology provides exceptional position control and repeatability for filling valve operation and container handling mechanisms. Variable frequency drives allow for precise speed control and energy optimization across different production requirements. The control system incorporates safety interlocks and emergency stop functions that protect operators and equipment while maintaining production continuity. Remote diagnostics capabilities enable predictive maintenance scheduling and rapid troubleshooting support from equipment manufacturers.

High-Speed Performance Characteristics

Throughput Optimization and Cycle Time Reduction

Linear filling machines excel in high-speed applications through optimized mechanical design and advanced control algorithms. The straight-line configuration eliminates the acceleration and deceleration forces associated with rotary motion, allowing for faster container indexing and reduced cycle times. Multiple filling stations can operate simultaneously without the mechanical constraints of circular motion, enabling higher throughput rates for given floor space requirements. The linear approach also facilitates easier integration of multiple product lines and container size changes without significant mechanical modifications.

Advanced timing systems coordinate container arrival, filling valve operation, and product discharge with microsecond precision. This level of timing control minimizes fill time while maintaining accuracy across varying container sizes and product viscosities. The ability to operate multiple filling heads independently allows for production flexibility and reduced downtime during changeovers. Speed optimization algorithms automatically adjust operating parameters based on product characteristics and quality requirements.

Precision Filling Technology and Volume Control

State-of-the-art filling valve technology ensures consistent volume delivery across high-speed operation cycles. Positive displacement pumps, servo-controlled piston systems, and time-pressure filling methods provide precise volume control regardless of production speed fluctuations. Electronic flow meters and weight-based feedback systems enable real-time volume verification and automatic adjustment capabilities. The precision filling technology maintains coefficient of variation levels below industry standards while operating at maximum throughput rates.

Multiple filling technologies can be integrated within a single linear type filling machine platform to accommodate different product characteristics and container requirements. Diving nozzles prevent foam formation in carbonated beverages, while bottom-up filling methods minimize product degradation in sensitive formulations. Anti-drip mechanisms and nozzle cleaning systems maintain product quality and prevent cross-contamination between production runs.

Industry Applications and Versatility

Pharmaceutical and Healthcare Manufacturing

The pharmaceutical industry relies heavily on linear filling machines for sterile liquid products including injections, oral solutions, and topical preparations. The clean design architecture and smooth surfaces facilitate thorough cleaning and sterilization procedures required for aseptic manufacturing environments. Compliance with current good manufacturing practices is achieved through detailed documentation capabilities, batch tracking systems, and validation protocols integrated into the control system architecture. The linear configuration provides excellent operator visibility for quality inspections and regulatory compliance monitoring.

Specialized features for pharmaceutical applications include isolator integration capabilities, clean-in-place systems, and steam-in-place sterilization compatibility. The mechanical design accommodates various container types including vials, ampoules, bottles, and syringes with minimal changeover requirements. Precision filling capabilities ensure accurate dosing for critical medications while maintaining sterility throughout the production process. Advanced monitoring systems track environmental conditions and provide comprehensive audit trails for regulatory submissions.

Cosmetics and Personal Care Production

Cosmetic manufacturers benefit from the versatility and precision of linear filling systems for products ranging from perfumes and lotions to shampoos and liquid soaps. The ability to handle varying viscosities and foam-sensitive products makes linear machines ideal for diverse cosmetic formulations. Container flexibility accommodates unique packaging designs and premium presentation requirements common in cosmetic applications. The smooth product handling prevents degradation of sensitive ingredients and maintains product aesthetics throughout the filling process.

Specialized nozzle designs prevent air entrapment and foam formation that could compromise product appearance and performance. Multi-product capabilities enable efficient production of product variants and seasonal formulations without extensive line modifications. The precision control systems maintain consistent fill levels critical for premium cosmetic presentation and consumer satisfaction. Integration with capping and labeling equipment creates complete packaging solutions for cosmetic production lines.

Economic Advantages and Return on Investment

Production Efficiency and Cost Optimization

Linear filling machines deliver significant economic advantages through reduced labor requirements and increased production throughput. Automated operation minimizes direct labor costs while improving consistency and reducing human error potential. The modular design approach allows for incremental capacity expansion as production requirements grow, protecting initial equipment investments while providing scalability options. Energy-efficient servo motor technology and optimized mechanical design reduce operational costs compared to traditional filling methods.

Reduced product waste through precision filling control directly impacts production costs and profit margins. The ability to achieve tight fill tolerances minimizes overfilling while ensuring regulatory compliance and customer satisfaction. Quick changeover capabilities maximize productive time and reduce setup costs when switching between products or container sizes. Comprehensive diagnostic systems minimize unplanned downtime and reduce maintenance costs through predictive maintenance capabilities.

Quality Assurance and Compliance Benefits

The inherent precision and repeatability of linear filling machines contribute to enhanced quality assurance and regulatory compliance capabilities. Automated data collection and statistical process control features provide comprehensive documentation for quality management systems. The consistent filling performance reduces quality-related costs including rework, customer complaints, and regulatory issues. Integration with quality control systems enables real-time monitoring and immediate corrective action when process variations occur.

Validation and qualification procedures are streamlined through standardized control systems and comprehensive documentation packages provided by equipment manufacturers. The mechanical design facilitates thorough cleaning validation and microbiological testing required for regulated industries. Audit trail capabilities and electronic batch records support regulatory compliance while reducing administrative overhead associated with manual documentation systems.

FAQ

What are the key advantages of linear filling machines over rotary systems?

Linear filling machines offer several distinct advantages including easier integration with existing conveyor systems, better operator access for maintenance and quality control, simplified mechanical design that reduces complexity, and the ability to handle varying container sizes with minimal adjustments. The straight-line configuration eliminates the centrifugal forces present in rotary systems, making them ideal for fragile containers and foam-sensitive products. Additionally, linear systems typically require less floor space and offer more flexibility for future expansion or modification.

How do linear filling machines maintain accuracy at high speeds?

High-speed accuracy is achieved through advanced servo motor control systems that provide precise timing and positioning, sophisticated filling valve technology that compensates for speed variations, real-time monitoring systems that detect and correct deviations immediately, and optimized mechanical design that minimizes vibration and mechanical variation. Electronic feedback systems continuously monitor fill volumes and automatically adjust parameters to maintain target specifications regardless of production speed fluctuations.

What maintenance requirements are typical for linear filling machines?

Regular maintenance includes daily cleaning and sanitization procedures, periodic calibration of filling systems and sensors, lubrication of mechanical components according to manufacturer specifications, and replacement of wear items such as seals and gaskets on scheduled intervals. Preventive maintenance programs typically include monthly servo motor inspections, quarterly control system backups, and annual comprehensive system validation. Most modern systems provide diagnostic alerts and maintenance scheduling to optimize uptime and prevent unexpected failures.

Can linear filling machines handle multiple product types simultaneously?

Yes, modern linear filling machines can be configured with multiple product supply systems and independent filling stations to handle different products simultaneously. This capability requires careful design consideration for product segregation, cleaning protocols, and changeover procedures to prevent cross-contamination. Multi-product systems typically incorporate dedicated product pathways, separate control zones, and automated cleaning cycles for each product line. The flexibility makes these systems ideal for contract manufacturing and facilities producing multiple product variants.