Modern manufacturing facilities increasingly rely on automated production systems to meet growing consumer demand while maintaining consistent quality standards. Linear type filling machines have emerged as a cornerstone technology in packaging operations across multiple industries, offering unparalleled precision and efficiency. These sophisticated systems transform traditional manual filling processes into streamlined automated workflows that significantly reduce labor costs and minimize product waste. Companies seeking to optimize their production capabilities often find that linear type filling machines provide the perfect balance between operational flexibility and high-volume throughput requirements.

Understanding Linear Type Filling Machine Technology

Core Design Principles and Mechanisms

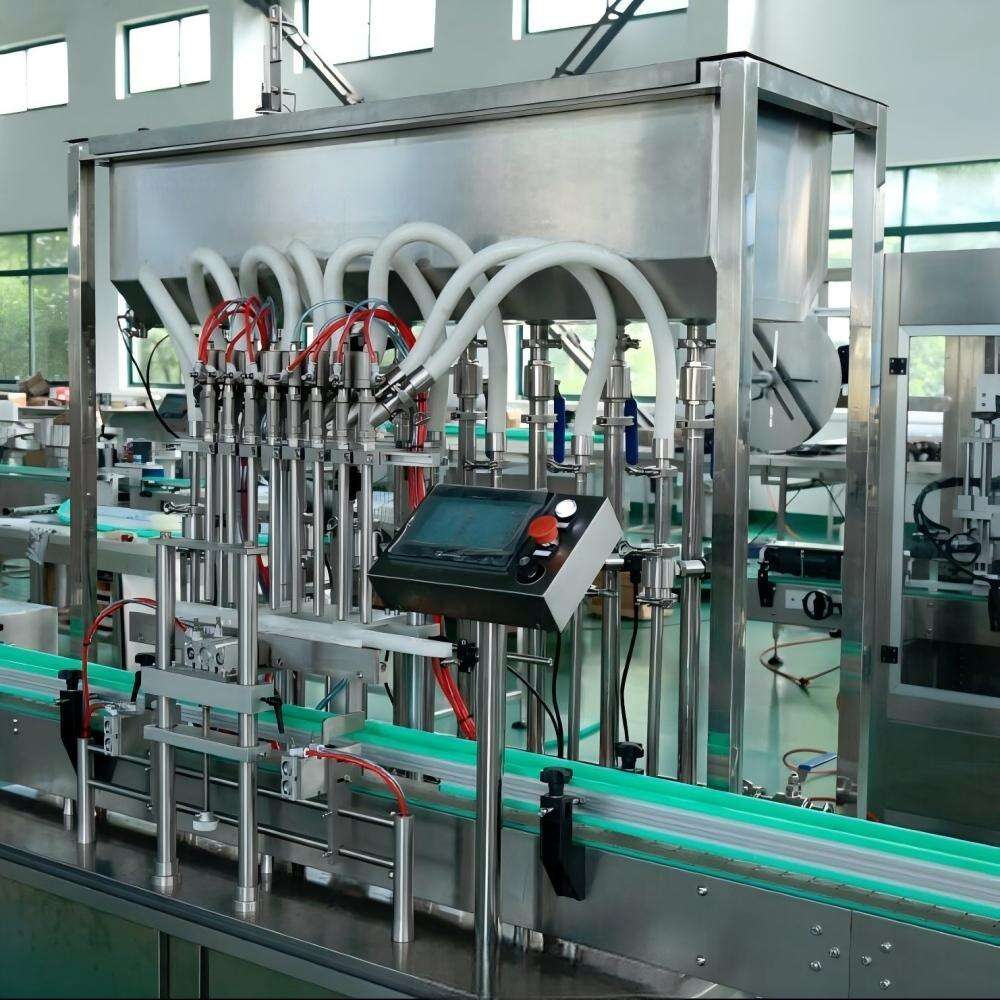

Linear type filling machines operate on a straightforward conveyor-based system where containers move in a straight line through various filling stations. This design philosophy prioritizes accessibility and maintenance simplicity, allowing operators to easily monitor and adjust the filling process at any point along the production line. The linear configuration enables precise control over fill volumes, timing sequences, and quality checkpoints that ensure consistent product delivery. Unlike rotary systems, linear type filling machines offer superior flexibility for handling different container sizes and shapes without requiring extensive changeover procedures.

Advanced Control Systems and Precision Technology

Contemporary linear type filling machines incorporate sophisticated programmable logic controllers and servo-driven mechanisms that deliver exceptional accuracy across diverse product viscosities. These systems utilize advanced flow meters, load cells, and optical sensors to monitor filling parameters in real-time, automatically adjusting dispensing volumes to maintain target specifications. The integration of human-machine interfaces allows operators to easily modify filling parameters, track production metrics, and diagnose potential issues before they impact overall equipment effectiveness. Modern linear type filling machines also feature self-cleaning capabilities and sanitary design elements that comply with stringent food and pharmaceutical industry regulations.

Operational Advantages in Production Environments

Enhanced Production Efficiency and Throughput

Linear type filling machines demonstrate remarkable efficiency improvements compared to manual filling operations, typically increasing production speeds by 300-500% while simultaneously reducing labor requirements. The continuous flow design eliminates bottlenecks commonly associated with batch processing methods, enabling manufacturers to achieve consistent hourly output rates that support ambitious production targets. These systems excel in applications requiring frequent product changeovers, as the linear configuration allows rapid cleaning and reconfiguration between different formulations or container types. Production managers appreciate how linear type filling machines integrate seamlessly with upstream and downstream equipment to create comprehensive automated production lines.

Quality Control and Product Consistency

The precision capabilities of linear type filling machines directly translate to improved product quality and reduced waste generation throughout manufacturing operations. Advanced weight-checking systems and vision inspection technologies built into these machines detect underfilled or overfilled containers, automatically rejecting defective units before they proceed to packaging stages. This automated quality control approach minimizes human error while ensuring that every product meets established specifications for volume, appearance, and overall presentation. Linear type filling machines also maintain detailed production logs and statistical process control data that support continuous improvement initiatives and regulatory compliance requirements.

Industry Applications and Versatility

Food and Beverage Manufacturing

Food and beverage manufacturers rely heavily on linear type filling machines for processing liquid products ranging from dairy items and juices to sauces and cooking oils. These systems accommodate the strict hygiene standards required in food production while handling products with varying viscosities and particulate content. The sanitary design features of modern linear type filling machines include CIP (clean-in-place) systems, FDA-approved materials, and easy-to-clean surfaces that prevent contamination and support HACCP compliance programs. Many food processors choose linear type filling machines specifically for their ability to handle both hot-fill and cold-fill applications without compromising filling accuracy or production speed.

Pharmaceutical and Chemical Industries

Pharmaceutical manufacturers depend on linear type filling machines for precise dispensing of liquid medications, syrups, and chemical formulations where accuracy directly impacts product efficacy and safety. These systems provide the containment capabilities necessary for handling hazardous or controlled substances while maintaining the sterile environments required for pharmaceutical production. Linear type filling machines designed for pharmaceutical applications often incorporate specialized features such as nitrogen blanketing, explosion-proof electrical components, and validated cleaning procedures that support FDA validation requirements. Chemical processors similarly benefit from the robust construction and chemical-resistant materials used in industrial-grade linear type filling machines.

Economic Benefits and Return on Investment

Labor Cost Reduction and Operational Savings

Implementing linear type filling machines typically results in substantial labor cost reductions as these systems can perform the work of multiple manual operators while delivering superior consistency and speed. The automation provided by linear type filling machines allows companies to reallocate human resources to higher-value activities such as quality assurance, equipment maintenance, and process optimization. Additionally, the reduced physical demands on workers lead to lower injury rates and improved workplace safety metrics that translate to reduced insurance costs and workers' compensation claims. Many manufacturers report complete payback on their linear type filling machines investment within 18-24 months through combined labor savings and increased production capacity.

Waste Reduction and Material Efficiency

The precision dispensing capabilities of linear type filling machines significantly reduce product waste compared to manual filling methods, often cutting material losses by 2-5% of total production volume. This waste reduction directly improves profit margins while supporting sustainability initiatives by minimizing environmental impact and resource consumption. Linear type filling machines also reduce container waste by virtually eliminating overfill situations that can cause packaging failures or contamination issues. The consistent fill levels achieved by these systems optimize packaging efficiency and reduce shipping costs by maximizing the number of units that fit within standard shipping containers.

Technical Specifications and Configuration Options

Capacity Ranges and Speed Capabilities

Modern linear type filling machines are available in configurations ranging from small-scale laboratory units processing 50-100 containers per hour to high-speed industrial systems capable of filling 3000+ units per hour. The modular design of most linear type filling machines allows manufacturers to start with basic configurations and add filling heads or auxiliary equipment as production demands increase. Speed capabilities depend on factors such as container size, product viscosity, and filling volume, with typical installations achieving optimal performance through careful matching of machine specifications to specific application requirements. Linear type filling machines designed for high-speed operations often incorporate advanced container handling systems and automated cap placement to maintain consistent throughput rates.

Customization and Integration Features

Leading manufacturers of linear type filling machines offer extensive customization options to accommodate unique product characteristics and production requirements. These modifications can include specialized pumping systems for handling particulate-laden products, heated filling assemblies for temperature-sensitive materials, and explosion-proof designs for volatile chemicals or solvents. Integration capabilities allow linear type filling machines to communicate with enterprise resource planning systems, providing real-time production data and enabling predictive maintenance scheduling. Many modern linear type filling machines also support remote monitoring and diagnostic capabilities that allow technical support teams to troubleshoot issues and optimize performance without requiring on-site visits.

Maintenance and Long-term Performance

Preventive Maintenance Requirements

Linear type filling machines require systematic preventive maintenance programs to ensure optimal performance and extend equipment lifespan beyond typical 15-20 year service expectations. Daily maintenance tasks typically include cleaning filling nozzles, checking pneumatic connections, and verifying calibration accuracy, while weekly procedures involve more thorough cleaning of product contact surfaces and inspection of wear components. The accessible design of linear type filling machines simplifies maintenance activities compared to more complex rotary systems, allowing in-house technicians to perform most routine service tasks without specialized training. Proper maintenance of linear type filling machines not only prevents costly unplanned downtime but also maintains filling accuracy and product quality standards throughout the equipment lifecycle.

Troubleshooting and Technical Support

Modern linear type filling machines incorporate diagnostic systems that help operators quickly identify and resolve common operational issues such as filling inconsistencies, container jams, or sensor malfunctions. User-friendly touchscreen interfaces display error codes and troubleshooting guidance that enable production staff to address many problems without requiring specialized technical expertise. Most manufacturers of linear type filling machines provide comprehensive technical support including remote diagnostics, on-site service, and operator training programs that ensure maximum equipment utilization. The straightforward mechanical design of linear type filling machines typically results in lower service costs and shorter repair times compared to more complex automated systems.

FAQ

What container types work best with linear type filling machines

Linear type filling machines accommodate virtually any rigid container including glass bottles, plastic containers, metal cans, and pouches with proper fixturing. The linear design excels at handling containers with unusual shapes or varying heights that might cause difficulties in rotary systems. Most linear type filling machines can process container sizes ranging from small vials to large industrial containers with minimal changeover requirements.

How do linear type filling machines compare to rotary filling systems

Linear type filling machines offer superior accessibility for maintenance and cleaning while providing more flexibility for container changeovers compared to rotary systems. While rotary systems may achieve higher maximum speeds, linear type filling machines typically provide better cost-effectiveness for small to medium production volumes and applications requiring frequent product changes. The choice between systems depends on specific production requirements, available floor space, and operational preferences.

What training is required for operating linear type filling machines

Operating linear type filling machines typically requires 2-3 days of hands-on training covering machine operation, basic troubleshooting, and routine maintenance procedures. Most manufacturers provide comprehensive training programs that include both theoretical instruction and practical exercises using actual production scenarios. Additional specialized training may be required for applications involving hazardous materials or sterile processing requirements.

Can linear type filling machines handle products with particulates or varying viscosities

Yes, linear type filling machines can be configured with specialized pumping systems and filling nozzles designed to handle products containing particles, fibers, or ingredients with varying flow characteristics. Options include progressive cavity pumps for thick products, peristaltic pumps for gentle handling, and gravity-fed systems for free-flowing liquids. The key is selecting the appropriate filling technology and nozzle design for specific product characteristics.